Where is all the timber needed to construct more Passivhaus buildings going to come from?

This was a question (paraphrased) asked by a person at a recent presentation I gave about the international Passivhaus Standard. They were clearly under the impression that it was easier / better / necessary to use a timber frame construction system to build to the standard.

I shouldn’t have been surprised since I was presenting on behalf of Architype, where I worked at the time. Architype are leaders in designing Passivhaus buildings and timber buildings, so the majority of the Passivhaus buildings I presented were timber construction.

It is a common misconception that timber is best for Passivhaus construction.

Ironically, there is also a misconception that ‘natural materials’ are not suitable for Passivhaus, therefore ruling out the use of timber.

Neither is true!

The international Passivhaus Standard is a performance standard: many different construction systems are possible.

In theory, any type of construction system can be used to meet the international Passivhaus Standard, since it is a performance standard. In practice, some systems have limitations that make it much more challenging to meet the requirements of the standard.

In this blog post, we’ll take a look at 5 categories of Passivhaus construction. The categories and the photos are from the Passivhaus Database, a project of the Passive House Institute, the Passivhaus Dienstleistung GmbH, the IG Passivhaus Deutschland and the iPHA (International Passive House Association) and Affiliates.

The categories are (in alphabetical order):

- Insulated Concrete Forms (ICF)

- Masonry

- Mixed (Timber and Masonry)

- Steel

- Timber

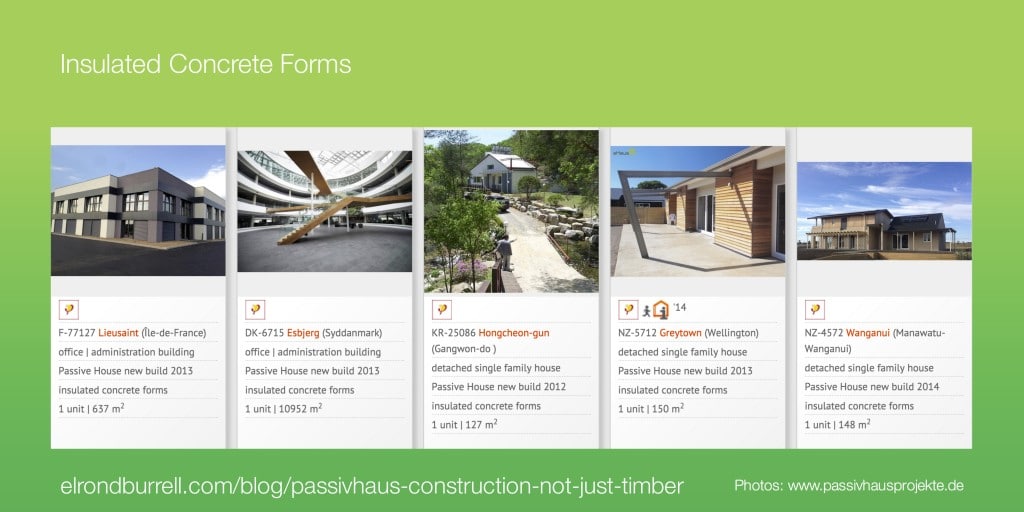

1. Passivhaus Construction: Insulated Concrete Forms (ICF)

Insulated concrete forms are a popular Passivhaus construction system for single family houses in many parts of the world. It is easy to see why; the insulated forms automatically create a continuous thermal envelope, the concrete core forms a continuous airtight layer, the system provides integrated structure and building envelope, it’s easy to build with and is usually cost effective.

Even when ICF isn’t used for the complete building envelope, it is sometimes used for parts of the building envelope below ground, or even just for the footings below a ground slab.

At the time of writing, there are 30 certified Passivhaus buildings in the ICF category on the Passivhaus Database. Of these, 18 are single family houses, 10 are multi-unit residential buildings and 2 are office buildings. The buildings aere from a range of places across the globe; Europe, the US, NZ, Korea.

ICF: suitable for Passivhaus Construction, large or small.

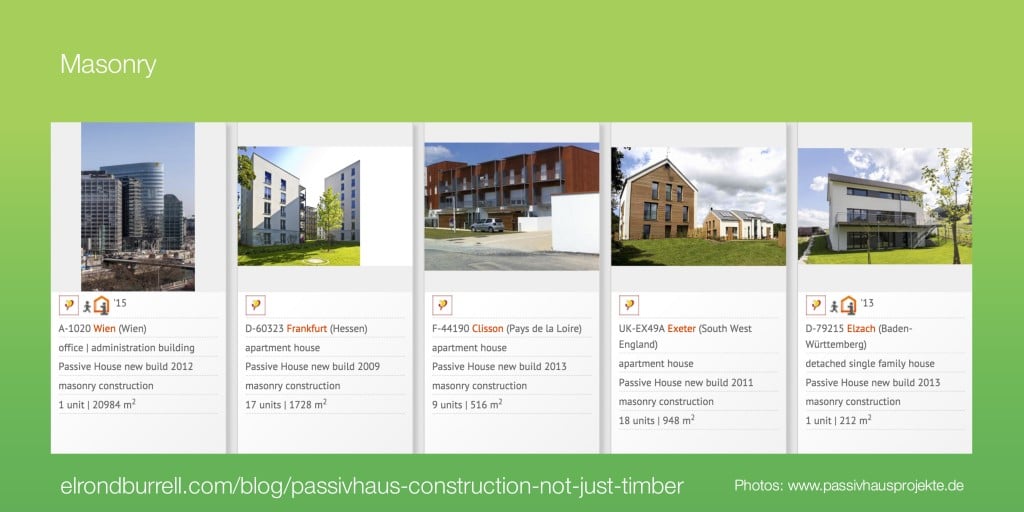

2. Passivhaus Construction: Masonry

Masonry, in it’s many forms, is the dominant (‘traditional’) construction system in many parts of the world. When I first encountered Passivhaus architecture, it was German architecture, so I assumed masonry was the typical Passivhaus construction. Once I understood the standard better, I realised this isn’t the case.

Masonry Passivhaus construction can be externally insulated. Or it can take the form of cavity construction with insulation filling the cavity.

Externally insulated masonry is fairly typical Passivhaus construction in Germany. And to attain Passivhaus component certification, a Passivhaus window needs to achieve the stringent requirements when detailed in an externally insulated masonry wall. It is a very effective means of creating a continuous and high-performance thermal envelope. It does place some constraints on the external aesthetic, though, and usually a render (plaster) finish is applied.

Cavity construction allows for masonry or brick cladding, or render, or indeed many other options. In the UK, cavity Passivhaus construction has been relatively popular. This is in part due to the desire to continue the heritage of clay brick faced architecture and in part because it is the ‘traditional’ construction method in the UK.

With cavity construction, the cavity may need to be wider than typical to provide enough insulation if the building has a relatively high heat loss form factor. Regardless of the cavity width, the wall ties are thermal bridges across the cavity and therefore, low thermal conductivity wall ties are required. Low thermal conductivity wall ties are more expensive than typical wall ties and they are still thermal bridges, albeit very small ones. Therefore, it is worth the effort to ensure the design is optimised so excessive wall ties are not required for structural reasons.

Cavity construction does come with several design and installation challenges, in addition to the wall ties. For example, small and relatively inaccessible spaces can be created that need to be insulated. And, heavy cladding systems need to be thermally broken at foundation level

In all forms of masonry construction, the continuous airtight barrier is typically created with a plaster coat.

At the time of writing, there are 371 certified Passivhaus buildings in the Masonry category on the Passivhaus Database.

Masonry: suitable for Passivhaus Construction, traditional in many parts of the world.

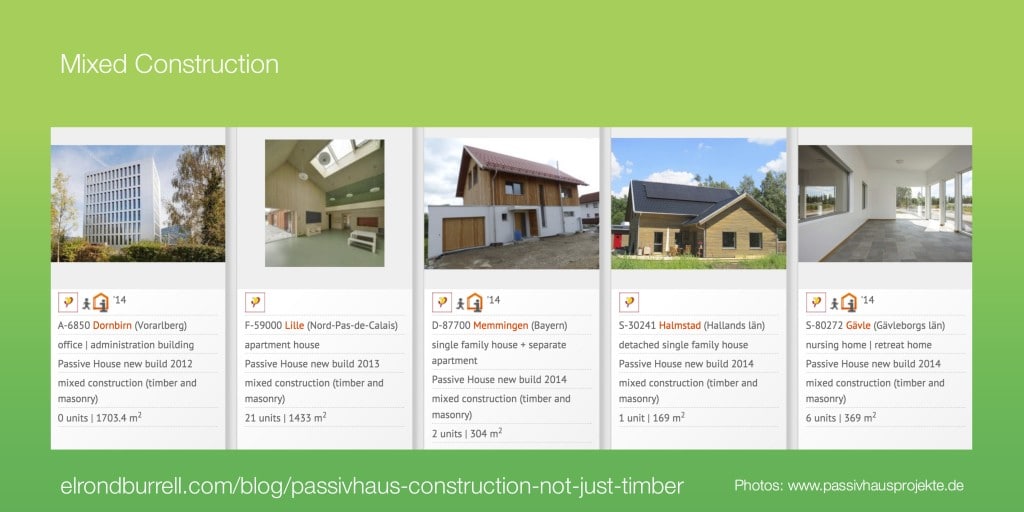

3. Passivhaus Construction: Mixed (Timber and Masonry)

It’s no big surprise that many buildings include a mixture of Passivhaus construction types. However, the Passivhaus Database only has one category for Mixed Construction: Timber and masonry. In reality, many buildings in other categories also have aspects of mixed construction. Most ICF buildings will have timber roofs, for example.

In many cases, the split between timber and masonry construction happens at ground level. Below ground construction, such as a basement, needs to be concrete, masonry or ICF. Above ground, timber is suitable.

In other cases, it is quite different, though. The left-hand example in the images above is the Life Cycle Tower (LCT1) which is a hybrid construction. The services and circulation core is reinforced concrete, the floors are hybrid engineered timber reinforced concrete and the frame and external shell is engineered timber. This building gets a mention (and features a great time-lapse video) in an earlier blog post about another building, the IZM, that also uses the same Passivhaus construction system.

Mixed construction has all the advantages and challenges of the respective construction systems. However, it has the added challenge of constructing multiple systems on the same site and then constructing the junctions between the different systems. For these reasons, it is best for inexperienced architects, designers and clients to aim to stick to the most appropriate single Passivhaus construction system for early projects.

At the time of writing, there are 145 certified Passivhaus buildings in the Mixed category on the Passivhaus Database.

Mixed Construction: suitable for Passivhaus Construction, but may bring additional challenges.

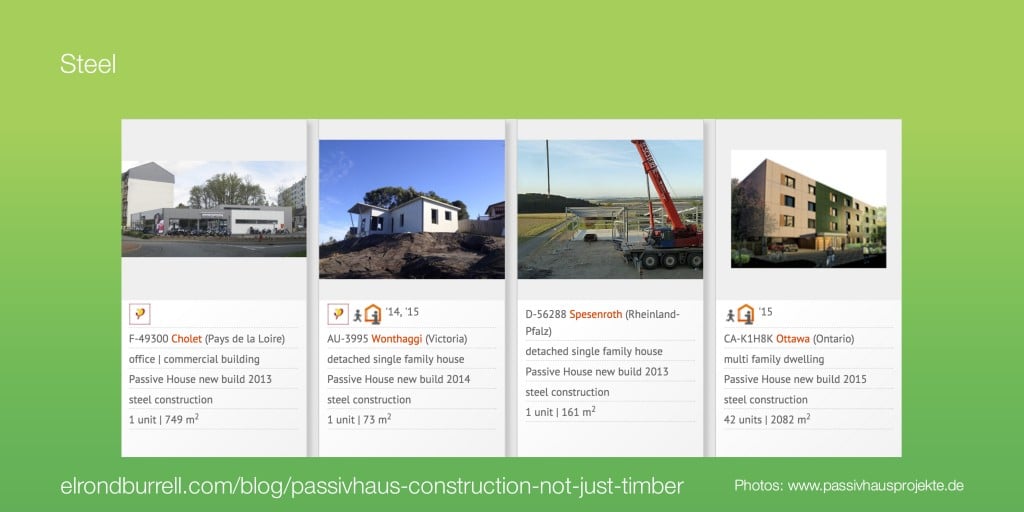

4. Passivhaus Construction: Steel

Although it is possible to utilise steel for passivhaus buildings, it is not a very popular choice to date.

Of the 4 examples illustrated above, actually only 2 are certified to the international Passivhaus standard, those on the left. (Including Superpod that was featured in a previous blog post.) One of the others is listed as a ‘Plus energie-Haus’ and the multi-unit residential building on the right was constructed in 2015 so still awaiting certification. There are, however, other steel-frame certified Passivhaus buildings that I am aware of that aren’t included in the Passivhaus Database.

Why so few steel Passivhaus buildings?

Perhaps because steel is perceived to be the most challenging Passivhaus construction system to work with?

Perhaps because it’s not so cost effective when large parts of the building envelope are solid / opaque?

Certainly, steel frame construction can introduce considerable thermal bridges when not integrated or considered from the very beginning. Steel column to concrete foundation details need particular attention to ensure the thermal envelope isn’t compromised. Equally, anywhere else where structure needs to pass through the thermal envelope will require close attention to eliminate thermal bridging.

The airtight barrier needs to be outside the steel frame in order to be continuous, but still inside the thermal envelope. This could be a sheathing board with all the joints taped, or it could be a membrane.

At the time of writing, there are 2 certified Passivhaus buildings in the Steel category on the Passivhaus Database.

Steel Construction: suitable for Passivhaus Construction, but particularly challenging?

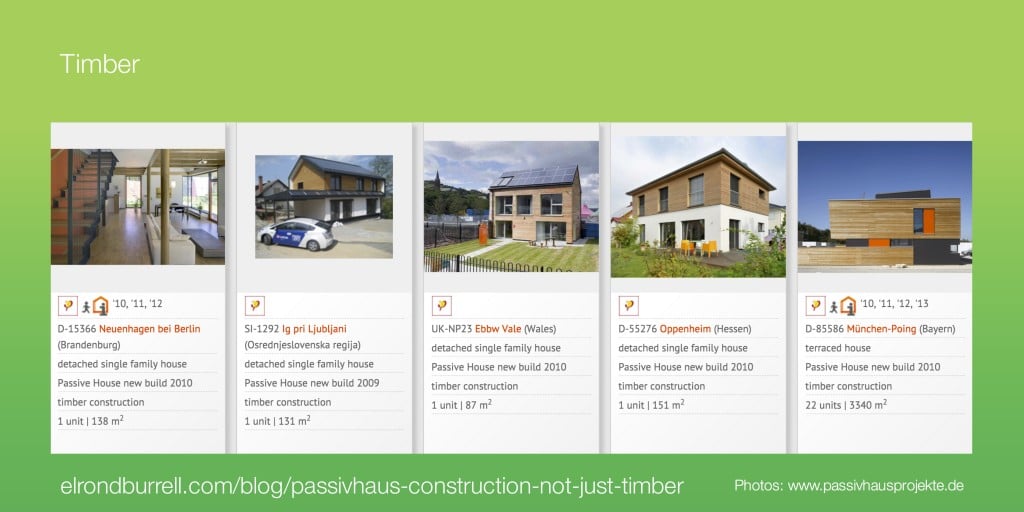

5. Passivhaus Construction: Timber

And finally, timber! Yes, timber is a suitable Passivhaus construction system. Timber in all its forms – structural framing, studwork, panels, mass timber – is suitable. And it is a popular choice for Passivhaus.

There are at least three good reasons for timber construction being popular for Passivhaus.

Firstly, it is a common method of construction in many parts of the world, even the ‘traditional’ method in some places.

Secondly, timber construction is generally light-weight. This makes it much easier for the crucial foundation details to be thermal bridge free. It also makes it easier to work with for self-builders, many who now choose to build to the Passivhaus standard. Where thermal mass is desirable, an exposed concrete floor slab and dense internal walls linings can provide all that is needed.

Thirdly, timber is an ecological choice. The environmental impact of responsibly sourced timber can be much less than masonry or concrete. Timber is an effective carbon capture and storage solution; CO2 is locked into the timber for as long as the building stands. Burning the timber or leaving it to biodegrade releases the CO2 (or worse, methane) into the atmosphere. Used appropriately it can also be a healthy building material and part of a vapour permeable construction assembly.

Timber Passivhaus construction still has challenges, though. Like cavity wall construction, small inaccessible spaces can occur, making it a challenge to install the insulation. And, the thermal envelope still needs to be continuous. Timber structure passing through the insulation is a thermal bridge. The airtight barrier needs to be continuous and timber structural members are typically not airtight due to the fibrous nature of timber and small cracks. Therefore, the airtight barrier will often need to be installed carefully in sequence in order to pass behind or around structural members. Also, watch out for structural gymnastics that require steel supports and need to be completely inside the thermal envelope to avoid thermal bridging.

The airtight barrier can be a sheathing (or racking) board or a membrane.

At the time of writing, there are 303 certified Passivhaus buildings in the Timber category on the Passivhaus Database.

Timber Construction: suitable for Passivhaus Construction, and ecological.

Passivhaus Construction: Choose Your Own Adventure!

The international Passivhaus standard is a performance standard. The materials and construction systems are not prescribed.

You get to choose.

Each Passivhaus construction system comes with advantages and with challenges. You should not assume that what worked on another project will necessarily be suitable for your project.

The location, region, economic situation, client preferences, design team preferences, ground conditions and many more factors all play a part in choosing the right Passivhaus construction system for a project. The form and aesthetic might be the strongest driver of the construction system.

The Passivhaus Standard introduces design constraints, but in and of itself should not be the sole determining factor in choosing a construction system.

Some additional resources:

- Passivhaus (Passive House) Database.

- Technical Guidance from the (UK) Passivhaus Trust: How to Build a Passivhaus – Rules of Thumb. See page 4 – 7 for System Choices.

Was this blog post helpful? Please send it to your friends and colleagues and share it on your favourite social media channel.

Enter your email at this link to subscribe. You’ll be notified of each new post and receive exclusive Passivhaus insights (not published on the blog) every other week direct to your inbox.

Hi, Interesting post. I always assumed that timber construction was most suitable for passivhaus due to its good thermal properties. Further, if the priority is to reduce the buildings impact on climate change then timber remains the only sustainable choice from the options that you have highlighed.

Hi Pat,

Thanks for your comment. In a very mild climate, timber might be considered to have “good thermal properties”, however, in a more temperate or cold climate, timber is a thermal bridge as it is around 3 times more conductive than insulation. You are right about the place of timber in the bigger picture of sustainability and that certainly does motivate a lot of people designing and building Passivhaus buildings.

Best wishes, Elrond

Eco-Slab will give you the best concrete slab, suspended or ground bearing.10 times faster, 1/3rd cheaper and miles greener. So simple, see 90 second video on Eco-Slab.com. Made for us by Jablite.

Bernard 07808790568