This is a Passivhaus Basics blog post that gives an overview of a specific aspect of the Passivhaus Standard.

The international Passivhaus Standard does not explicitly require mechanical ventilation. And yet almost every certified Passivhaus building includes a mechanical ventilation system with heat recovery.

What is mechanical ventilation with heat recovery (MVHR) and why is it needed in Passivhaus buildings?

Mechanical ventilation is familiar to most people. This leads to the assumption that a Passivhaus ventilation system is the same as other mechanical ventilation systems. It is not.

There are things that MVHR does not do. It is important to know what these are in order to understand the difference between Passivhaus MVHR and other types of ventilation.

And there are things that Passivhaus MVHR does do that other ventilation systems don’t, including ‘natural ventilation’. It is important to know what MVHR does do, as MVHR is vital to the consistent success of the passivhaus standard.

Mechanical ventilation with heat recovery (MVHR) is key to delivering the benefits the Passivhaus Standard promises – radical energy efficiency and exceptional comfort.

What is mechanical ventilation with heat recovery (MVHR)?

There are two main aspects to MVHR – mechanical ventilation and heat recovery.

Mechanical ventilation is simply a duct coming into the building with a fan blowing fresh air in and a duct going out of the building with a fan blowing stale air out. Since the fans are powered and controlled, the ventilation is considered “mechanical” as opposed to a ventilation system with no power and no control such as ‘natural ventilation’. There is probably mechanical ventilation in some form in the building you are in right now – such as mechanical extract ventilation from a bathroom or kitchen.

Heat recovery is using a heat exchanger that takes the heat from warm air and gives it to cold air. The air inside a building is typically warm because it has been heated in some way so that the rooms are comfortable to inhabit. On the other hand, outside air is typically colder than indoor air for a large part of the year. Often, outdoor air is colder overnight all year round. This is the case even in climates we generally consider to be warm. By using a heat exchanger, fresh cold outside air can be warmed up to a comfortable temperature by using the heat of the warm stale indoor air as it is extracted.

The two air paths never come into contact with each other, so stale air is not mixed with fresh air. No contamination or pollution from the extract air can get into the fresh supply air. Only heat is transferred in the heat exchanger. (Moisture can also be transferred in an energy or enthalpy exchanger, but that isn’t the subject of this post.)

Passivhaus mechanical ventilation with heat recovery is balanced whole house (or building) ventilation.

The amount of air that goes into the building through the MVHR matches the amount of air that comes out of the building through the MVHR. This gives control over the air movement and means that the maximum amount of heat can be recovered from the outgoing air. This is one of the reasons a Passivhaus building must be airtight. You can still open windows and doors whenever you like, though. Opening a window is a choice you make and in your control. You have no choice or control over infiltration and air leakage through a building envelope that is not airtight!

MVHR is also known as heat recovery ventilation (HRV) and mechanical heat recovery ventilation (MHRV). In the context of a Passivhaus building, these terms all mean the same thing.

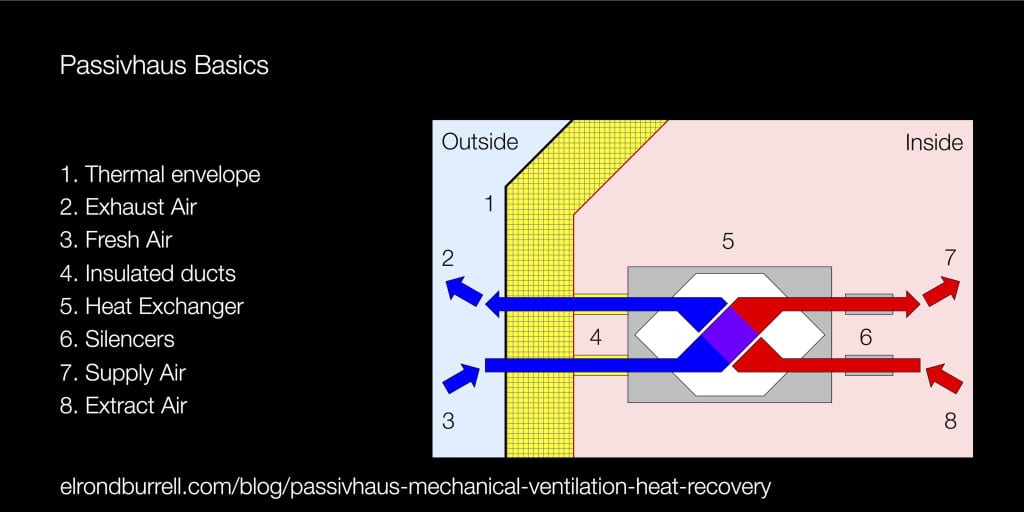

Mechanical ventilation with heat recovery in a Passivhaus building typically looks like the following:

- On the external façade, there are two grilles. One is for incoming fresh air and one is for exhaust stale air.

- Behind each of the grilles is a short length of duct going directly to the MVHR unit. These ducts both have cold air inside. One duct has cold fresh air from the outside being blown into the building. The other duct has cold stale air being blown out of the building. Even though the latter has air from inside the building where it is warm, the heat has already been exchanged at this point so the air is cold. These two (cold) ducts need to be insulated from the (warm) inside of the building; they are effectively part of the thermal envelope. The insulation needs to be vapour impermeable to prevent condensation forming on these ducts. And, as part of the thermal envelope, these ducts also need to be airtight, sealed to the airtight barrier of the external fabric they pass through and sealed to the MVHR unit.

- These two ducts connect to the MVHR unit, where the air paths are also insulated.

- Inside the MVHR unit, the fresh incoming air passes through a filter to remove pollen, debris and pollution. This protects the heat exchanger from blocking and also ensures the indoor air is clean and healthy.

- Both supply and exhaust air streams pass through a counterflow heat exchanger. A counterflow heat exchanger can recover between 75 and 95% of the heat compared to a non-counterflow heat exchanger, which can only recover a maximum of 50% of the heat. Many MVHR units also have a by-pass function so that in summer when the outdoor air is warm, heat doesn’t need to be recovered. The “summer by-pass” function reduces any risk of overheating and is recommended!

- Both air streams have a small fan in them to blow the air in the right direction.

- Two ducts connect to the other side of the MVHR unit. One of these ducts goes to all the habitable rooms of the building to deliver fresh air. In a house, these are living rooms, dining rooms, bedrooms etc.. The other duct comes back to the MVHR from all the rooms where air is extracted. In a house, these are kitchens, bathrooms, toilets etc.. Both ducts may run from room to room, or branch out several times to reach all the necessary rooms.

- Extract air from the rooms also passes through a filter to remove any airborne dust and debris before entering the heat exchanger to preventing it from blocking.

- Both ducts have silencers on them close to the MVHR unit so that the sound of the fans, although very quiet, does not travel along the ducts and into the rooms. The international Passivhaus Standard requires that MVHR units are for all intents and purposes completely silent in all habitable rooms. The humming sound of a fan, even if it is very quiet, is uncomfortable and undesirable.

- Where a duct passes between different rooms, the duct has a “cross-talk” silencer to ensure that sounds don’t transfer between the rooms. If either duct passes through a fire rated part of the building, a fire damper is fitted.

- Where the ducts supply or extract air from rooms, there is a terminal on the wall or ceiling. The terminal can be a grille or another suitable kind of fitting.

Early in the development of the international Passivhaus Standard, there were several examples of buildings that also incorporated a “ground heat exchanger” (or “earth tubes”). Is this system, the fresh air passes through an underground duct to be pre-warmed by the ground, which is a stable temperature all year round, before it gets to the MVHR. This type of system is not necessary or recommended in Passivhaus buildings now.

There are several excellent examples of Passivhaus buildings in the book ”Passive House Design – Planning and design of energy-efficient buildings”. (Read my review here.) In each case, the MVHR system is clearly described and illustrated in drawings and diagrams. If you want to learn more about this subject, I highly recommend this book.

MVHR – fresh outdoor air is filtered and pre-warmed by heat recovered from the stale extract air. The fresh air is delivered where you need it inside, the stale air is expelled from the building.

Why do Passivhaus Buildings need MVHR?

There are three main reasons for MVHR in a Passivhaus building: comfort, energy efficiency and control.

The Comfort of MVHR.

The term “comfort” doesn’t really communicate fully what is meant in this case. In a Passivhaus building, the “comfort” that MVHR provides covers a whole range of important comfort and health aspects of indoor living.

- MVHR provides the right amount of fresh air for a healthy indoor environment for all the people in the building, not too much and not too little. Too little fresh air would have a negative effect on the indoor air quality as pollutants could build up. (This is what ‘natural ventilation’ typically does.) Too much fresh air would dry out the indoor air making it uncomfortable and aggravating any respiratory problems.

- MVHR removes odours, pollutants and stale air from the building. Cooking smells, furniture and fittings off-gassing (you know, that ‘new carpet’ type of smell), CO2 are all removed leaving the indoor air healthy, fresh and comfortable.

- MVHR also removed excess moisture from the building. This is critical for a healthy indoor environment. Despite how innocent the term “moisture” seems it is actually one of the big health hazards in buildings. Excess moisture leads to high humidity, condensation, dampness and mould. These are exactly the kind of conditions that lead to respiratory issues, including asthma.

- MVHR provides pre-warmed air at a comfortable temperature and at low velocity so there are no cold draughts.

- MVHR, in summer by-pass mode, can remove some of the hot indoor air during summer to help provide a pleasantly cool indoor environment. Typically, night ventilation with the MVHR or opening windows plays an equally important role during the hotter periods of summer.

The Energy Efficiency of MVHR.

The big question about MVHR energy efficiency is whether or not it saves more energy that it uses. The international Passivhaus Standard requires that the installed MVHR unit is 75% or more efficient. Many Passivhaus certified MVHR units are 90% or more efficient. This means that the fans are very low energy and for almost all of the year the MVHR uses less (electrical) energy than the (heat) energy it saves.

For comparison, heat pump Coefficient of Performance (COP) ratios are fairly well known. A COP of 3 or over is considered very good, if actually achieved. A Passivhaus certified MVHR with 80% efficiency could achieve a COP of 15.

To continue with this example, if a Passivhaus building had an 80% efficient MVHR with a specific fan power of 0.35Wh/m³, the MVHR would save more heat energy than it uses in electrical energy while it is 19°C or lower outside (1° cooler or more than inside). Even when the outdoor temperature was higher than this, it would still make sense to run the MVHR to get all the comfort and health benefits noted above. And the cost of doing so would be very low.

This must be understood in the context of a Passivhaus building where strict comfort criteria can be maintained all year round. This includes the MVHR providing the required amount of ventilation for comfort and health, and the indoor temperature being maintained at healthy levels. Questions of energy efficiency become irrelevant when a building is uncomfortable, unhealthy and not kept at a suitable temperature for human occupation (essentially 20°C according to the World Health Organisation).

To achieve the same health and comfort criteria with ‘natural ventilation’ is virtually impossible. And if it were possible, it would require a huge amount of heating to counter the effect of all the cold ventilation air and draughts.

It is recommended that a Passivhaus certified MVHR unit is used in a Passivhaus building. If a non-certified MVHR unit is used, a 12% penalty is taken off the stated efficiency. So if the manufacturer states the efficiency as 93% it will only be taken as 81% for Passivhaus. There are a number of reasons for this, but essentially it comes down to taking a conservative approach to ensure the design predictions are accurate. The Passivhaus certification of components, including MVHR, is very rigorous and ensures the stated efficiency is accurate.

Part of the accuracy is that the Passivhaus measure of MVHR efficiency is based on exhaust efficiency rather than supply efficiency. In simple terms, the exhaust efficiency reflects the temperature of the air leaving the building relative to outside air temperature. Supply efficiency reflects the temperature of the air being supplied into rooms relative to outside air temperature. Passivhaus takes the exhaust efficiency because the MVHR is effectively part of the thermal envelope and it is the heat losses of the MVHR that are considered. This includes heat gains from the fans, losses through the MVHR case, flow imbalance and air leakage from the MVHR. Losses through the case reduce the exhaust efficiency but actually increase the supply efficiency. Manufacturers tend to state supply efficiency and, therefore, it will be higher than a Passivhaus certified exhaust efficiency.

MVHR efficiency is dependent on the building having an airtight building envelope. If the building is not airtight, the MVHR will not be able to be balanced accurately as some air will be leaking in and out of the building through the fabric rather than passing through the MVHR. The air leaking in and out will also take warm air out of the building and bring cold air in.

The Control of MVHR.

Aside from the comfort and energy efficiency of MVHR, it also provides control of the ventilation. If we depend on ‘natural ventilation’, we are relying on air pressure, wind, stack effect and other unreliable factors to ensure we get adequate fresh air into our building. As well as being unreliable, these factors are mostly outside of our control.

With MVHR and an airtight building envelope, where, when, how and how much fresh air is brought into the building is all under our control. And the same for extract air – in a balanced ventilation system, stale and polluted extract air really does get expelled from the building in the way that it is intended to.

When more fresh air is needed, or more air needs to be extracted, the airflow rates can be increased. And we can do this knowing that the indoor air quality and comfortable temperatures will not be compromised.

And to be completely clear – windows and doors can still be opened as often and for as long as we desire. If windows and doors are left open for a long time when it is cold outside, of course cold air will come inside and the indoor temperature will drop. But as soon as we close the windows and doors, the indoor temperatures will rise quickly. In the meantime, we will still be comfortable because all the indoor surfaces are warm due to being well-insulated and thermal bridge free. And we can close the windows and doors to be comfortable, knowing there will still be adequate ventilation provided.

MVHR provides exceptional indoor comfort, radical energy efficiency, and equally importantly, it gives control over ventilation and indoor air quality.

MVHR does not …

- …provide air conditioning.

- …provide cooling, although cooling can be added to the ventilation system if required.

- …provide heating, although heating can be added to the ventilation system if required.

- …recirculate air. MVHR always supplies fresh air and extracts stale polluted air.

- …make indoor air unhealthy. The fresh air is filtered and typically more healthy than outdoor air coming straight in through an open window. Ducts must be clean when the system is commissioned and there is no reason why they would get dirty while in use.

- …dry the supply air out. Adequately ventilating a warm indoor space, by any means, with cold fresh air from outside will lead to the indoor air having a lower relative humidity than the outdoor air. This might seem a little drier than we are used to at first – simply because we are used to damp unhealthy levels of relative humidity indoors due to a lack of adequate ventilation! Where this might be a problem in very cold dry climates, and energy or enthalpy exchange unit might be necessary to recover the moisture from the indoor air as well as the heat.

- …extract directly from kitchen cookers. A recirculation hood should be used to scrub off grease etc. from the cooking. The MVHR extract should be some distance away in the same room so it can extract the pollutants and smells, but not get clogged up with grease.

MVHR does …

- …provide controlled constant fresh air.

- …filter incoming air to remove particulates, pollution, pollen etc. (Anecdotal evidence suggests that Passivhaus MVHR actually helps reduces asthma and reliance on asthma medication.)

- …filter extract air to stop the heat exchanger getting clogged up.

- …warm supply air to a comfortable temperature using heat exchanged from the extract air. That is, the heat stays inside the building rather than getting thrown away.

- …save more (heating) energy than the (electrical) energy the fans use.

- …remove moisture & excess humidity preventing condensation & mould.

- …remove indoor pollutants including CO2, VOCs etc..

What is Mechanical Ventilation with Heat Recovery (MVHR)?

Mechanical Ventilation with Heat Recovery is fresh clean air delivered where you need it at a comfortable temperature.

Mechanical ventilation with heat recovery (MVHR) uses low energy fans to blow air gently and quietly into the building and blow the same amount of air out of the building. The heat in the warm air being extracted is recovered and used to warm the fresh air coming into the building.

Adequate ventilation for human health and comfort is often not provided in buildings. The international Passivhaus Standard ensures that healthy comfortable ventilation is provided consistently throughout a Passivhaus building. Wamr temperatures are maintained, fresh clean air provided and pollutants and stale air is removed from the building.

The MVHR is part of the thermal envelope and is highly energy efficient.

Mechanical ventilation with heat recovery gives building occupants full control over their ventilation. They can open windows when they want to. But even more importantly, they can close windows when they want to (eg for security or to shut out noise pollution) and know that they will still have adequate ventilation and exceptional comfort.

All of these aspects make MVHR essential for any high-performance building, and indispensable for the international Passivhaus Standard.

Was this blog post helpful? Please send it to your friends and colleagues and share it on your favourite social media channel.

Enter your email at this link to subscribe. You’ll be notified of each new post and receive exclusive Passivhaus insights (not published on the blog) every other week direct to your inbox.